RIGHT SIDE

RIGHT SIDE

"Right Side" is a project created to solve a problem well-known to skaters:

the wear and tear on shoes caused by contact with the skateboard.

The objective is therefore to protect the shoe without losing the aesthetic factor. In fact, one of the challenges was to make the product not only functional but also aesthetically attractive, thanks to its essential and fluid lines.

"Right Side" is a project created to solve a problem

well-known to skaters: the wear and tear on shoes caused

by contact with the skateboard.

The objective is therefore to protect the shoe without

losing the aesthetic factor.

In fact, one of the challenges was to make the product

not only functional but also aesthetically attractive,

thanks to its essential and fluid lines.

HOW IT WORKS

RIGHT SIDE

is positioned on the exterior of the shoe and is held firmly in place both by the laces, which secure the front section, and by an internal tab that is held down by the wearer's foot,

thereby locking the rear section.

Watch the video below to learn more.

BACKGROUND

MATERIAL

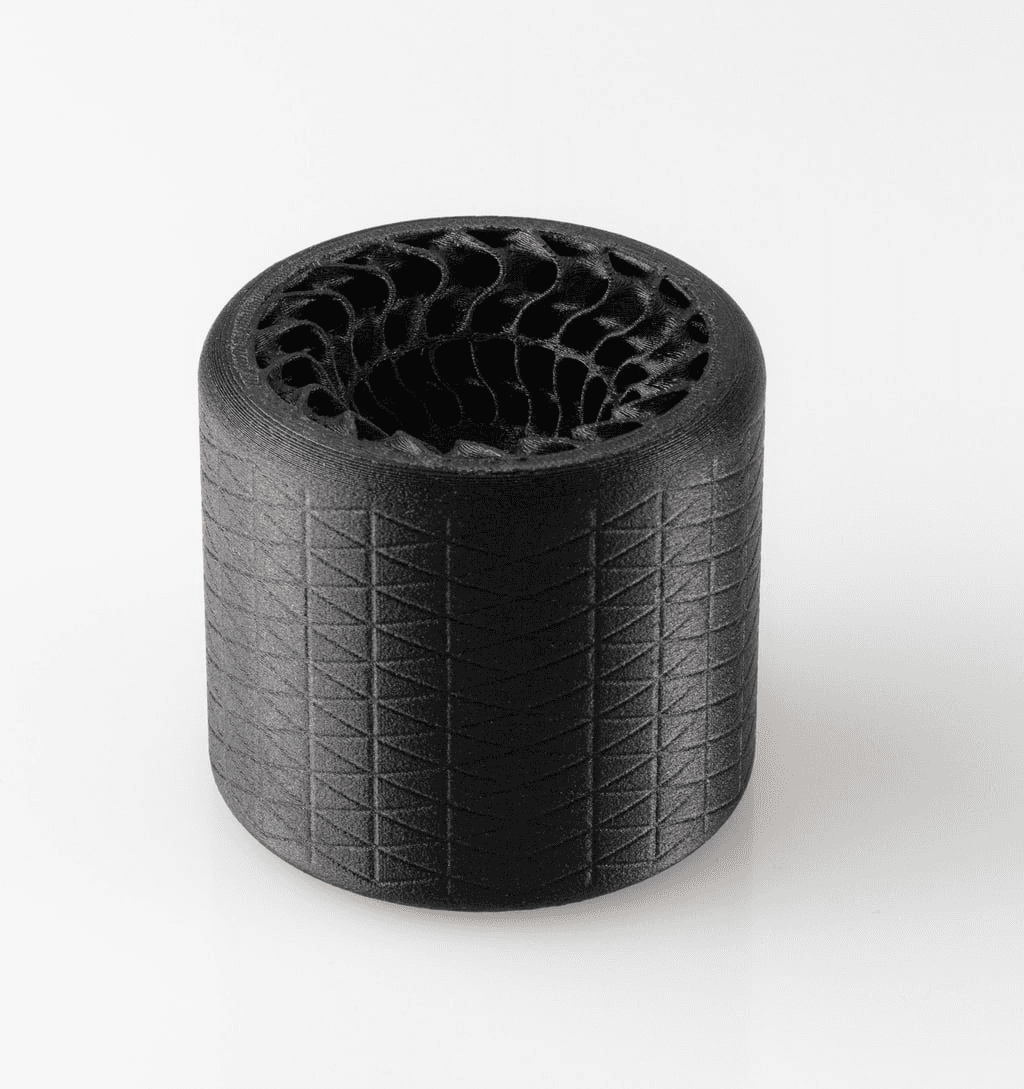

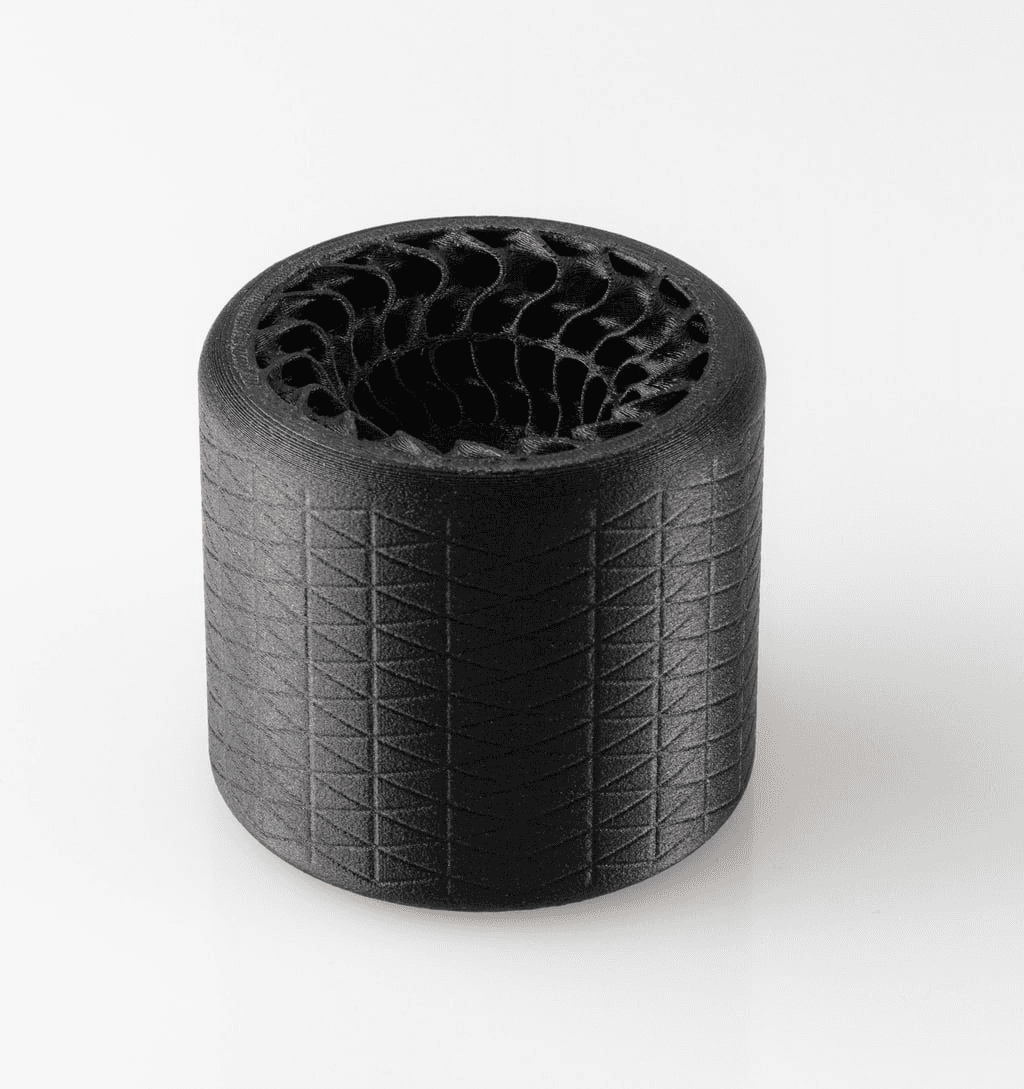

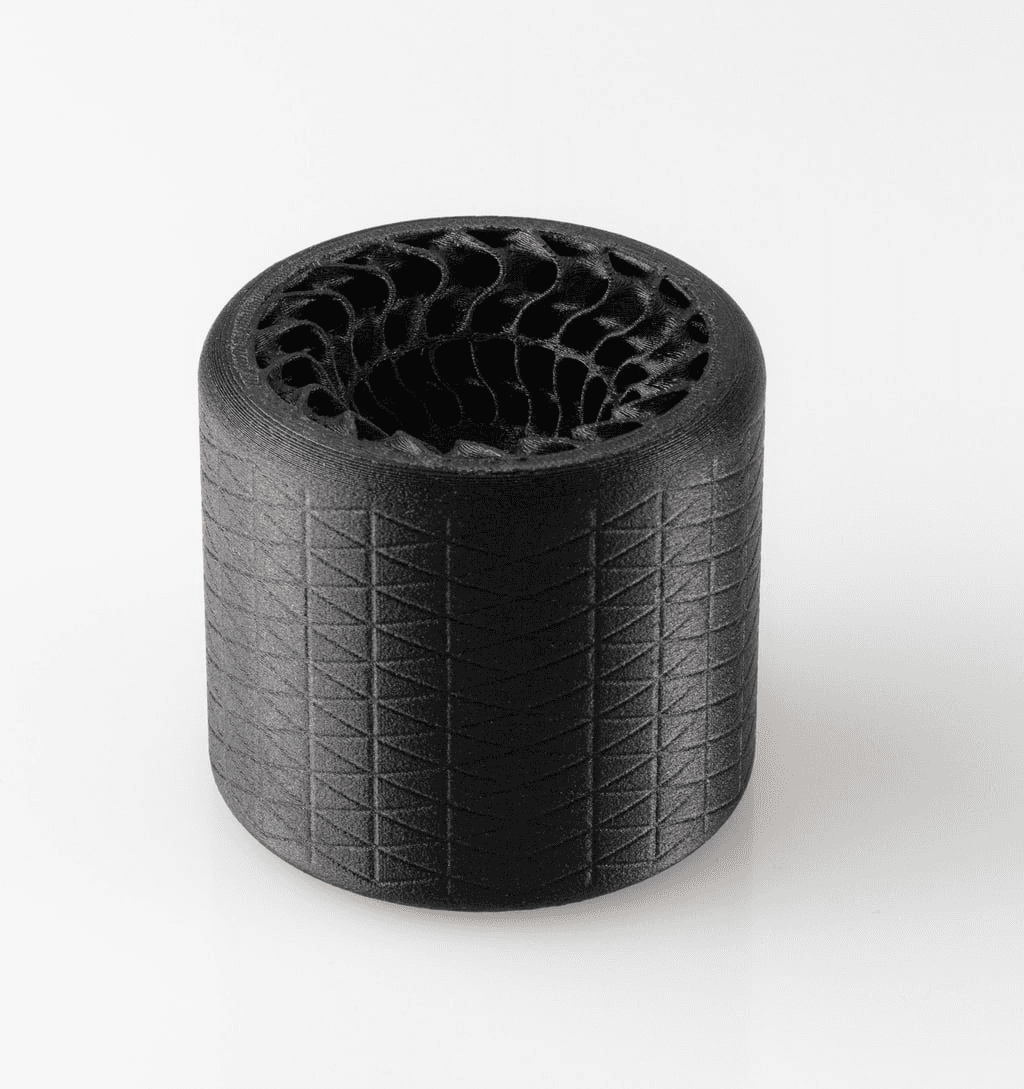

PERSPECTIVE VIEWS

TPU

The product's intended material is

Thermoplastic Polyurethane (TPU).

Given its properties and ease of molding,

it is the material capable of withstanding tension

and abrasion without significantly interfering

with the foot's movement.

FIRST PROTORIPE

TEST_1

RIGHT SIDE_1

The first version of the "right side" had a slightly different structure; it only covered a part of the shoe's side and was held to the shoe

by a small tongue that went into the shoelace hole and

by adhesive placed on the inside.

After producing and testing a prototype, I realized that

the stability was not good and that some parts of the shoe

were still affected by wear. Therefore, in the final version,

I extended the structure, allowing for both greater coverage and the possibility of being secured by the laces, thus solving both issues.

HAND MADE PROTOTIPE

PROTOTIPE

The prototype was created by layering thin fabric and grid-textured fibers, which were soaked in a liquid solution of PVA glue and water, to try and imitate the resistance and elasticity of TPU.

HOME

BACKGROUND

PERSPECTIVE VIEWS

TPU

The product's intended material

is Thermoplastic Polyurethane (TPU).

Given its properties and ease of molding,

it is the material capable of withstanding

tension and abrasion without

significantly interfering

with the foot's movement.

MATERIAL

FIRST PROTORIPE

HOW IT WORKS

RIGHT SIDE

is positioned on the exterior of the shoe and is held firmly

in place both by the laces, which secure the front section,

and by an internal tab that is held down by the wearer's foot,

thereby locking the rear section.

Watch the video below to learn more.

TEST_1

RIGHT SIDE_1

The first version of the "right side" had a slightly different structure; it only covered a part of the shoe's side

and was held to the shoe

by a small tongue that went into the shoelace hole

and by adhesive placed on the inside.

After producing and testing a prototype, I realized that

the stability was not good and that some parts of the shoe

were still affected by wear. Therefore, in the final version,

I extended the structure, allowing for both greater coverage

and the possibility of being secured

by the laces, thus solving both issues.

HAND MADE PROTOTIPE

PROTOTIPE

The prototype was created by layering thin fabric and grid-textured fibers, which were soaked in

a liquid solution of PVA glue

and water, to try and imitate

the resistance and elasticity of TPU.

HOME